Angle Head

Reliable CNC Angle Head Manufacturers

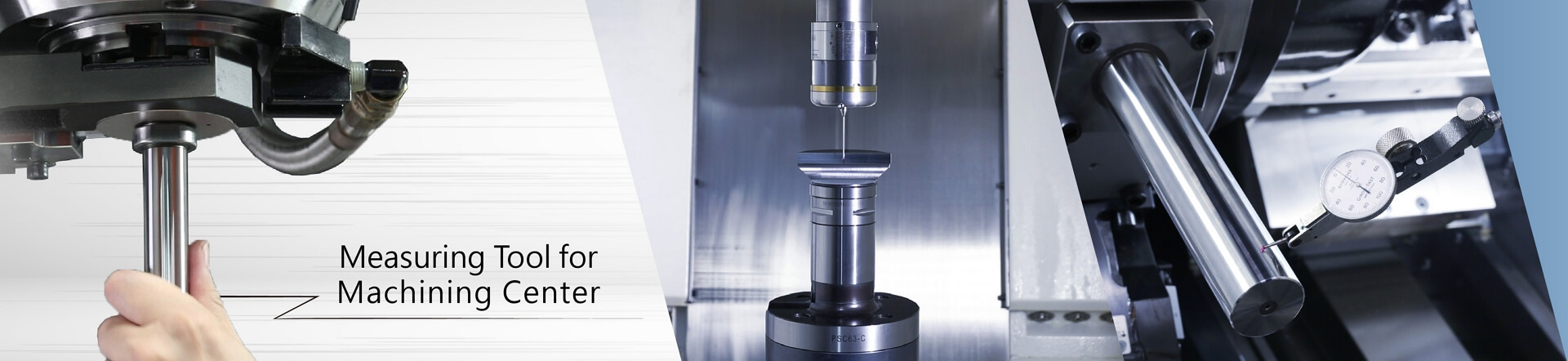

SYIC uses high-precision P4 class bearings and ground gears for all angle head series to minimize operational noise and temperature elevation. Every angle head holder undergoes a thorough temperature rise test before being shipped.

What Is The Importance of Angle Heads?

The angle head introduces angular flexibility to the machining process by allowing the tool to approach the workpiece at various angles. This adaptability is crucial for reaching challenging areas and executing intricate cuts with utmost precision. SYIC angle head holder can be used for side machining or even specific angle machining and helps you save production costs. It not only saves the expensive cost of purchasing another machine but also reduces the accuracy deviation caused by rotating and clamping the workpiece again.

SYIC Supports Different Types of Choices

As a leading angle head supplier, we offer a suitable series for drilling, tapping, milling, or grooving according to your machining demand whether it’s light, medium, or heavy-duty machining. For the design of output, we can provide 90°, universal type, and specific fixed angle type for you. If you have any questions about how to choose angle heads, feel free to contact us!