Knowledge Article

|

In limited machining space, interference issues may occur during the machining process, which are often key factors affecting production efficiency and product quality.

Among SYIC products, which products can be selected to optimize production and minimize interference? |

|

|

Time is money! How to maximize profits with the same amount of time and resources is a key concern for everyone. Improving efficiency can not only reduce costs, enhance corporate competitiveness, shorten delivery time, and improve employees’ quality of life, but also contribute to energy saving and carbon reduction, playing a role in protecting the environment. So, how can we improve production efficiency? |

|

|

During the cutting process, three critical factors are chip removal, heat dissipation, and ensuring effective cutting rather than extruding. First, efficient chips removal prevents extruding of chips on the workpiece surface so it reduces tools wear and improves surface finish of workpieces. Second, cutting generates heat that makes the temperature rise on both of tools and surface of workpieces. Excessive temperature may cause the tool edge deformation and result in inaccurate workpiece dimensions. Effective heat dissipation extends tool life and enhances machining quality. Moreover, effective cutting reduces friction and pressure during machining, thereby improving efficiency and precision. |

|

|

In metalworking, tool holder is a crucial connection between the machine spindle and the cutting tool. Selecting the right tool holder can improve the production efficiency and prolong the tool use-life. It plays a significant role in controlling the quality and cost. So, how to choose the right tool holder for machining? SYIC offers a variety of tool holder clamping series. This article introduces the appropriate tool holder clamping series for specific machining needs to help customers achieve optimal production efficiency. |

|

|

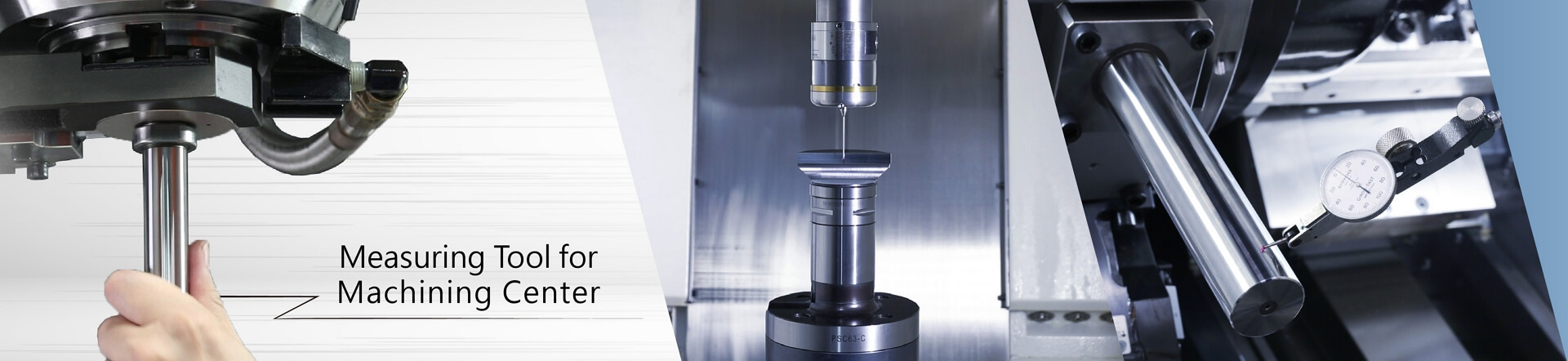

To produce a high-quality workpiece, it is essential not only to use high-performance tool holders and cutting tools on an efficient machine but also to inspect the workpiece's dimensions, accuracy, and surface roughness after machining. Besides these, what else can we do to achieve high-precision machining? SYIC suggests “implementing regular machine inspection” is an essential step. What measuring tools for machining center does SYIC offer? Let SYIC introduce to you! |

|

|

Metalworking has played a crucial role in the development of human civilization. From early manual processing to NC numerical control machines, and now to CNC computerized numerical control machines, the evolution has been significant. With the advent of machines, tool holders became essential for connecting machine and cutting tools. The interface between tool holders and machine involves various taper designs. Currently, three major types of tool holder tapers are widely used in machining: 7:24 taper, 1:9.98 HSK hollow taper, and 1:20 PSC polygon taper series. |

|

|

Tool holders can experience varying degrees of rust, impacting their performance and longevity. Rust can affect the contact between the tool holder taper and the machine spindle, leading to vibrations during machining and a shortened spindle lifespan. Want to know what maintenance steps can effectively prevent your tool holder from rusting, affecting the processing quality and tool holder service life? Let SYIC, a top CNC tool holders manufacturer based in Taiwan, tell you! |

|

|

In terms of equipment inspection, SYIC provides spindle master bars, ATC alignment tool set, SOG spindle origin gauge, and other tools, becoming the defense team for machines. Spindle collisions can lead to excessive runout accuracy, affecting workpiece processing accuracy and surface roughness. Additionally, collisions can impact the accuracy of machine tool changer systems, leading to tool change failures or even damaging spindles and tool holders. |