Introduction of Tool Holder Tapers

Metalworking has played a crucial role in the development of human civilization. From early manual processing to NC numerical control machines, and now to CNC computerized numerical control machines, the evolution has been significant. With the advent of machines, tool holders became essential for connecting machine and cutting tools. The interface between tool holders and machine involves various taper designs. Currently, three major types of tool holder tapers are widely used in machining: 7:24 taper, 1:9.98 HSK hollow taper, and 1:20 PSC polygon taper series.

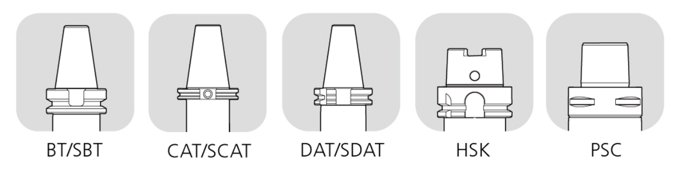

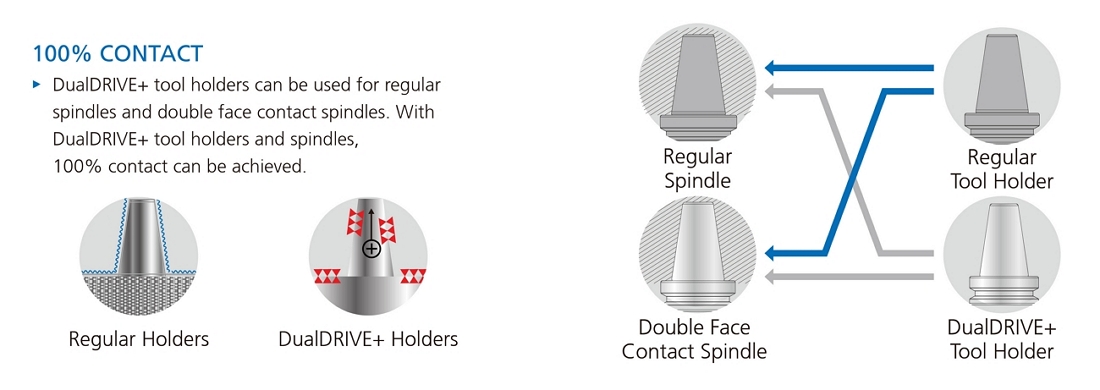

Tool holders come in a variety of types, designed according to national standards. Machines install tool holders, securely clamping cutting tools to create the diverse art of metalworking. Standards include Japanese standard BT (MAS 403 & ISO 7388-2), German standard DAT (DIN 69871-A & ISO 7388-1), international standard HSK (ISO 12164) and American standard CAT (ANSI/ASME B5.50). Considering these standards, except for HSK series, BT, CAT, and SK are all 7:24 taper types. 7:24 taper series allows for quick tool clamping, easier manufacturing, and lower costs. However, the industrial sector continually evolves, and 7:24 taper series has limitations, particularly in high speed rotations where the spindle internal hole expands, causing axial and radial dimensions in unstable repeat positioning accuracy.

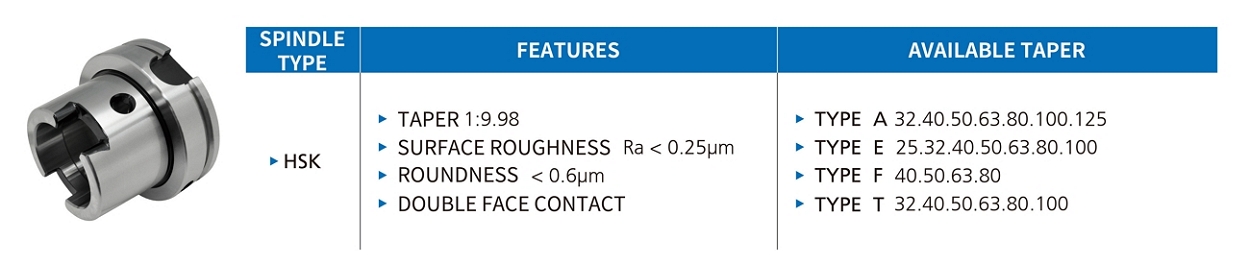

HSK hollow taper series was incorporated into German DIN standard in 1996. Modern machining process often requires higher revolutions to increase feed rates and cutting speed. The design of HSK hollow shank decreases weights by 40% compared with BT holders. With double face contact and high torque transmission in X axis and Z axis, HSK is ideal for high speed machining.

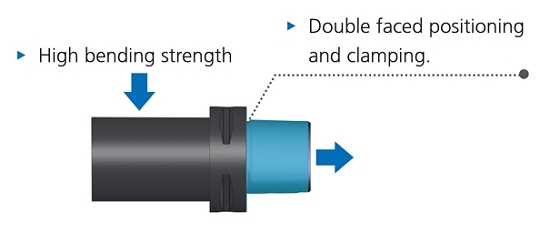

1:20 PSC polygon taper series has been included in the international ISO 26623 standard. Its original name, CAPTO, is originated from Latin, meaning "I firmly grasp." It has ultra-high torque transmission, bending strength, and superior repeat positioning accuracy, making it highly efficient. It is suitable for CNC lathes and turn-mill machines, providing applications for turning, milling, and drilling, etc.

The widely used BT, CAT, and SK series, HSK hollow taper series suitable for high speed machining, and PSC series, which boasts high rigidity and superior repeat positioning accuracy, can be diversely applied to lathes, turning centers and multi-tasking machines. Each taper type brings its own set of unique advantages to various machining tasks.

The industrial revolution brought about significant advancements, sparking brilliance and driving continuous operation of human civilization. As a part of machine tool industry, SYIC is committed to fulfilling our mission and responsibility by supplying tool holders which meet various industrial standards. We aim to deliver our products to every location with CNC machine tools across five oceans and seven continents, contributing to the advancement of human civilization and intelligent manufacturing.